Toolmaking & Engineering in Wilsdruff near Dresden

On March 1, 1980 the company „Werkzeug- und Maschinenbau Peter Wennrich“ was founded in Kesselsdorf. Since November 1, 2009 the family business is continued in second generation. A Ltd. was founded, whereas the original business „Werkzeug- und Maschinenbau Peter Wennrich“ still exists. Here you find a detailed company history. Our company „Geschwister Wennrich GmbH” is certified in according to ISO 9001:2015.

Do you have any questions? Please contact us by phone +49 35204 / 392 275 or by E-Mail.

We are your professional partner for:

- Processing of all kinds of metal and several plastic materials

-

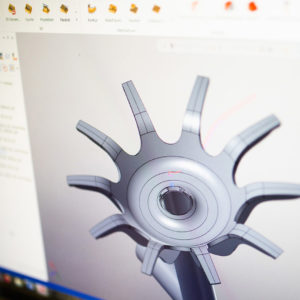

Machining

(milling, engraving, turning - CNC and conventional technology) -

Welding of copper, aluminum, stainless steel

(Tungsten Inert Gas welding (TIG), Metal Inert Gas welding (MIG), Metal Active Gas welding (MAG), autogenous welding, electric arc welding, e.g. copper welding (0,3-30mm on current-carrying parts), water and oil-tight welding) - flat grinding

-

Wire-cut EDM

(Electrical Discharge Machining) - jig and caliber manufacturing

-

Tool manufacturing

production of bending, punching/blanking, cutting/stamping tools, and fixture construction

Technology – Our Machinery

Milling

CNC-Machining center: | 2100x720x1200 mm (vertical) 2100x1000x1400 mm (horizontal) |

|---|---|

CNC-Machining center: | 600x500x500 mm |

Grob 350 5ax Universal-Machining center: | Working distances in X, Y and Z axis in mm: 600/770/805 Feedrate max in X, Y and Z axis in m per min: 65/42/90 Accuracy (ISO230-2 from 15.03.2006) Two-sided position uncertainty in X, Y and Z axis in mm: 0.006 Two-sided repeat accuracy of positioning A in X, Y and Z axis in mm: 0.004 |

CNC-Milling machine: | 1160x640x500 mm |

|---|---|

CNC-Machining center: | 300x450x300 mm |

G550 5-axis Universal-Machining center: | Working travels in X-/Y‘-/Z-axis (mm): 800/1,020/970 Max. speeds in X-/Y‘-/Z-axis (m/min): 65/50/80 Positioning accuracy in X-/Y‘-/Z-axis (mm): 0.006 |

2 CNC-Machining center (1x with 4th axis): | 1100x500x600 mm |

CNC-Machining center: |

|---|

2100x720x1200 mm (vertical) 2100x1000x1400 mm (horizontal) |

CNC-Machining center: |

600x500x500 mm |

Grob 350 5ax Universal-Machining center: |

Working distances in X, Y and Z axis in mm: 600/770/805 Feedrate max in X, Y and Z axis in m per min: 65/42/90 Accuracy (ISO230-2 from 15.03.2006) Two-sided position uncertainty in X, Y and Z axis in mm: 0.006 Two-sided repeat accuracy of positioning A in X, Y and Z axis in mm: 0.004 |

2 CNC-Machining center (1x with 4th axis): |

1100x500x600 mm |

CNC-Milling machine: |

1200x640x600 mm |

CNC-Machining center: |

300x450x300 mm |

G550 5-axis Universal-Machining center: |

Working travels in X-/Y‘-/Z-axis (mm): 800/1,020/970 Max. speeds in X-/Y‘-/Z-axis (m/min): 65/50/80 Positioning accuracy in X-/Y‘-/Z-axis (mm): 0.006 |

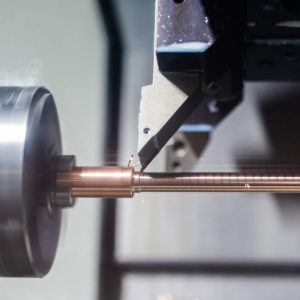

Turning

CNC-lathe (with driven tools): | 300×600 mm |

|---|---|

CNC-lathe (chuck-machine 42mm): | 250×500 mm |

Cycle Turning lathe: | 406×1000 mm |

Cycle Turning lathe: | 600×1800 mm |

CNC-lathe (with driven tools): |

|---|

300×600 mm |

CNC-lathe (chuck-machine 42mm): |

250×500 mm |

Cycle Turning lathe: |

406×1000 mm |

Cycle Turning lathe: |

600×1800 mm |

EDM

AGIE Wire-Cut Electrical Discharge machine (water bath): | Traverse: 550x350x400 mm Component may be larger than the travel and weigh a maximum of 300 kg. Buildt 2019 |

|---|---|

Sinking EDM machine AGIE-Intigral II: | Buildt 1997 |

AGIE Wire-Cut Electrical Discharge machine (water bath): |

|---|

Traverse: 550x350x400 mm Component may be larger than the travel and weigh a maximum of 300 kg. Buildt 2019 |

Sinking EDM machine AGIE-Intigral II: |

Buildt 1997 |

Grinding

Face grinding: | 800x400mm |

|---|---|

Wet grinding: | 800x400mm |

Pressing/Stamping

Toggle lever press: | up to 160 Tons |

|---|---|

Hydraulic press: | up to 25 Tons |

Exzenterpress: | 40 Tons |

Welding

WIG-Welding: | up to 600 Ampere |

|---|---|

MIG-Welding: | up to 500 Ampere |